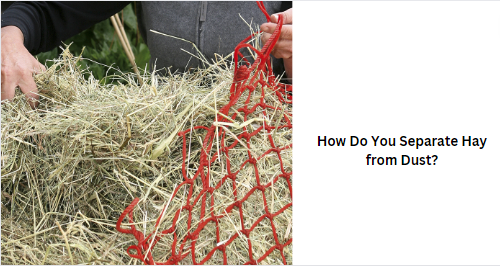

How Do You Separate Hay from Dust?

Hay is a crucial component of livestock feed, providing essential nutrients for animals to thrive. However, ensuring the quality of hay can be challenging, as it often contains dust and other impurities that can compromise its nutritional value and palatability.

In this article, we will explore effective methods for separating hay from dust to ensure the provision of high-quality feed for livestock.

Introduction to Separating Hay from Dust

Quality hay plays a significant role in animal nutrition, providing essential nutrients such as protein, fiber, and minerals.

However, dust accumulation on hay can reduce its nutritional content and pose health risks to animals. Therefore, separating hay from dust is essential to maintain its quality and ensure the well-being of livestock.

Methods of Separating Hay from Dust

There are two primary methods for separating hay from dust: manual and mechanical techniques. Each method has its advantages and limitations, depending on factors such as the scale of operation and available resources.

Manual Separation Techniques

Manual separation techniques involve handpicking or using screening methods to remove dust particles from hay. While manual methods may be labor-intensive, they can be effective for small-scale operations or when mechanical equipment is not available.

Handpicking

Handpicking involves visually inspecting each batch of hay and removing visible dust particles by hand. While this method is time-consuming, it allows for precise removal of impurities and ensures high-quality feed for animals.

Screening

Screening involves passing hay through a mesh screen to separate dust particles from the larger hay fibers. This method is relatively simple and cost-effective, making it suitable for small farms or homesteads.

Mechanical Separation Techniques

Mechanical separation techniques utilize machinery to remove dust from hay quickly and efficiently. These methods are ideal for large-scale operations where manual labor is impractical or time-consuming.

Air Blasting

Air blasting involves using compressed air to blow dust particles off the surface of hay. This method is highly efficient and can remove a significant amount of dust in a short period, making it suitable for industrial-scale hay processing.

Vibrating Screens

Vibrating screens use mechanical vibrations to separate hay fibers from dust particles. These screens are equipped with mesh screens of varying sizes, allowing for precise control over particle size distribution and removal of impurities.

Cyclonic Separation

Cyclonic separation utilizes centrifugal force to separate dust particles from hay. This method is highly effective and can remove fine dust particles that other techniques may miss. However, it requires specialized equipment and may be more costly to implement.

Factors to Consider for Effective Separation

Several factors should be considered when choosing a method for separating hay from dust, including:

· Moisture content: Wet hay may clump together, making it difficult to separate from dust. Therefore, it is essential to ensure that hay is properly dried before processing.

· Particle size: Dust particles come in various sizes, ranging from fine powder to larger debris. Choosing the appropriate screening or separation method depends on the size distribution of dust particles present in the hay.

· Equipment efficiency: The efficiency and throughput of the separation equipment will impact the overall effectiveness of the process. It is crucial to select machinery that can handle the required volume of hay and achieve the desired level of dust removal.

Benefits of Separating Hay from Dust

Separating hay from dust offers several benefits, including:

· Improved animal health: Clean, dust-free hay reduces the risk of respiratory issues and digestive problems in livestock.

· Enhanced nutritional value: Removing dust particles from hay helps preserve its nutritional content, ensuring that animals receive the essential nutrients they need for growth and development.

Tips for Maintaining Quality Hay

To maintain the quality of hay and minimize dust contamination, consider the following tips:

· Proper storage: Store hay in a clean, dry environment to prevent moisture buildup and minimize exposure to dust and contaminants.

· Regular inspection: Inspect hay bales regularly for signs of mold, mildew, or insect infestation, and remove any contaminated or damaged bales promptly.

Conclusion

Ensuring the quality of hay is essential for providing nutritious feed for livestock. Farmers can minimize dust contamination and maintain high-quality hay for their animals by employing effective separation techniques and implementing proper storage practices.

FAQs (Frequently Asked Questions)

1. How does dust affect the quality of hay?

Dust accumulation on hay can reduce its nutritional content and pose health risks to animals, leading to respiratory issues and digestive problems.

2. What are some common mechanical separation techniques for hay?

Common mechanical separation techniques include air blasting, vibrating screens, and cyclonic separation.

3. Why is it important to maintain quality hay for livestock?

Quality hay provides essential nutrients for livestock, supporting their overall health and well-being.

4. What factors should be considered when choosing a hay separation method?

Factors such as moisture content, particle size, and equipment efficiency should be considered when selecting a hay separation method.

5. How can farmers minimize dust contamination in hay storage?

Farmers can minimize dust contamination by storing hay in a clean, dry environment and regularly inspecting bales for signs of mold or mildew.

You May Also Like

Wellhealthorganic.com:lemon-juice-know-home-remedies-easily-remove-dark-spots

June 5, 2023

Financial Planning for Veterinarians: How Disability Insurance Fits Into the Picture

August 31, 2023